31 Mar Grease Is The Word

There are many useful reasons for using oil and grease in the world: component lubrication; fried eggs; corrosion protection; chips; anti-spatter welding spray; fried egg and chips. Incidentally, the last one is Mrs Metal Guru’s favourite dinner! Equally, there are many reasons why you wouldn’t want it entering your shot blasting system, which it usually does through contaminated work pieces. Once inside, it’s a nightmare to get out and will infect everything, especially the abrasive operating mix. And once the abrasive is affected, well you know how that gets everywhere in and around the machine. However, this time it’s not just energy its transferring, it’s the oil. Onto everything it touches. Like a greasy King Midas. The effects this causes can be split into two categories: problems with the process, and problems with the final product.

Introducing Amapure! The wonder degreasing mineral abrasive which sets each particle of oil in its sights and hunts it down until it is removed from the process

First let’s deal with the process.

One of the major impacts of oil in the operating mix is to make the individual particles stick together, which can then block the filter cartridges when removed from the system. This in turn reduces air flow and the system’s ability to successfully clean the operating mix of fine material and dust, thus creating a fine operating mix. And as you all read and understood my last blog, you’ll know all the issues this can cause. Just in case you’ve slept since reading that, a quick reminder that a fine operating mix can:

- Reduce both coverage and cleaning power, thereby increasing blast times

- Change surface roughness profile. Not great for subsequent coating

- Increase wear in the machine, especially to wheel blades

- Reduce productivity and profitability

I think we can all agree that’s not ideal. In general, around the machine, the abrasive will be sticky, almost magnetic, in its behaviour. It won’t move well around areas where it’s meant to flow smoothly. Filters can also be affected. Not just in their performance – getting clogged – but also the risk of fire can increase if there is oil or grease in there. Not an aspect to be taken lightly.

When it comes to the product, besides all the above-mentioned issues that come from a fine operating mix, grease and oil remaining on a “cleaned” surface can attract unwanted dust to the surface. If you’re applying a coating after blasting, both the unwanted dust and greasy surface can have a negative effect on that. And let’s face it, after spending all that time and effort on blast cleaning a part, you’d be pretty annoyed if it came out of the machine greasy. And your customers would not be best pleased either! That’s why some manufactures have to employ a further washing process after blasting. And that costs cold hard cash.

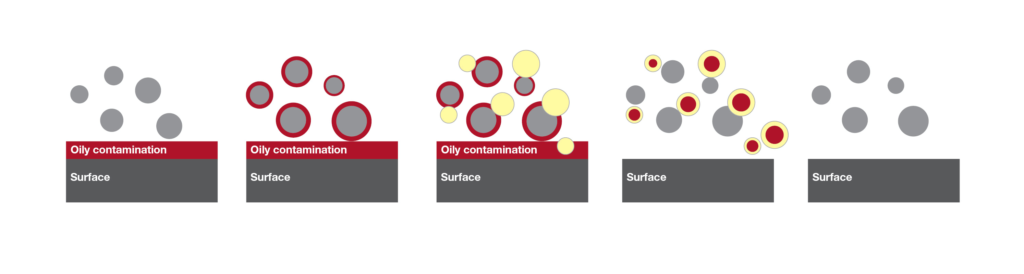

“Oh, if only I could purify my shot blasting system to get rid of this nasty oil”, I hear you cry. You could install one of those washing processes I mentioned. Or replace your whole hoppers worth of abrasive every few days. Our sales team would love that solution! Well fear no more, dear reader, a much more sensible solution is at hand. Introducing Amapure! The wonder degreasing mineral abrasive which sets each particle of oil in its sights and hunts it down until removal from the process occurs. The Amapure particles absorb the oil, and then themselves get removed by the air wash separator. After just a few litres, and 30-60 minutes (depending just how bad your contamination is), your problem is gone. Until your next greasy work piece enters your shot blast machine! But don’t get mad when this happens, just add regular doses of Amapure to purify (well done marketing department!) your system. And if you combine it with Ervin Amasteel or Stainless abrasive, you have your ideal blasting solution.