What is Shot Blasting?

An essential part of any metal treatment process; shot blasting, also commonly referred to as sand blasting or grit blasting, involves cleaning your metal through using abrasive techniques. This helps remove any impurities from the product and helps prep the surface for its intended use. This can be as simple as providing an additional level of protection for the material through tempering or preparing the surface for further treatment.

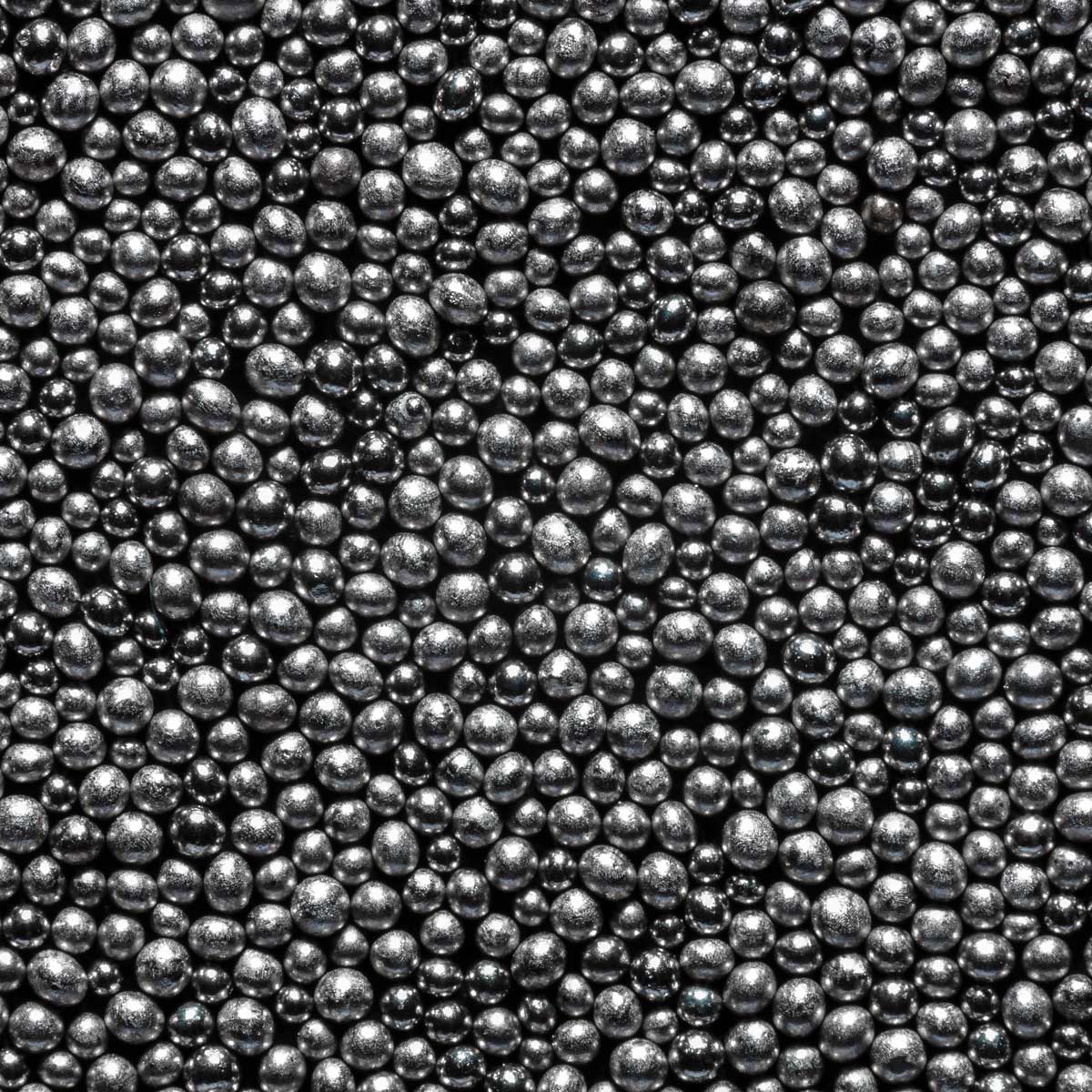

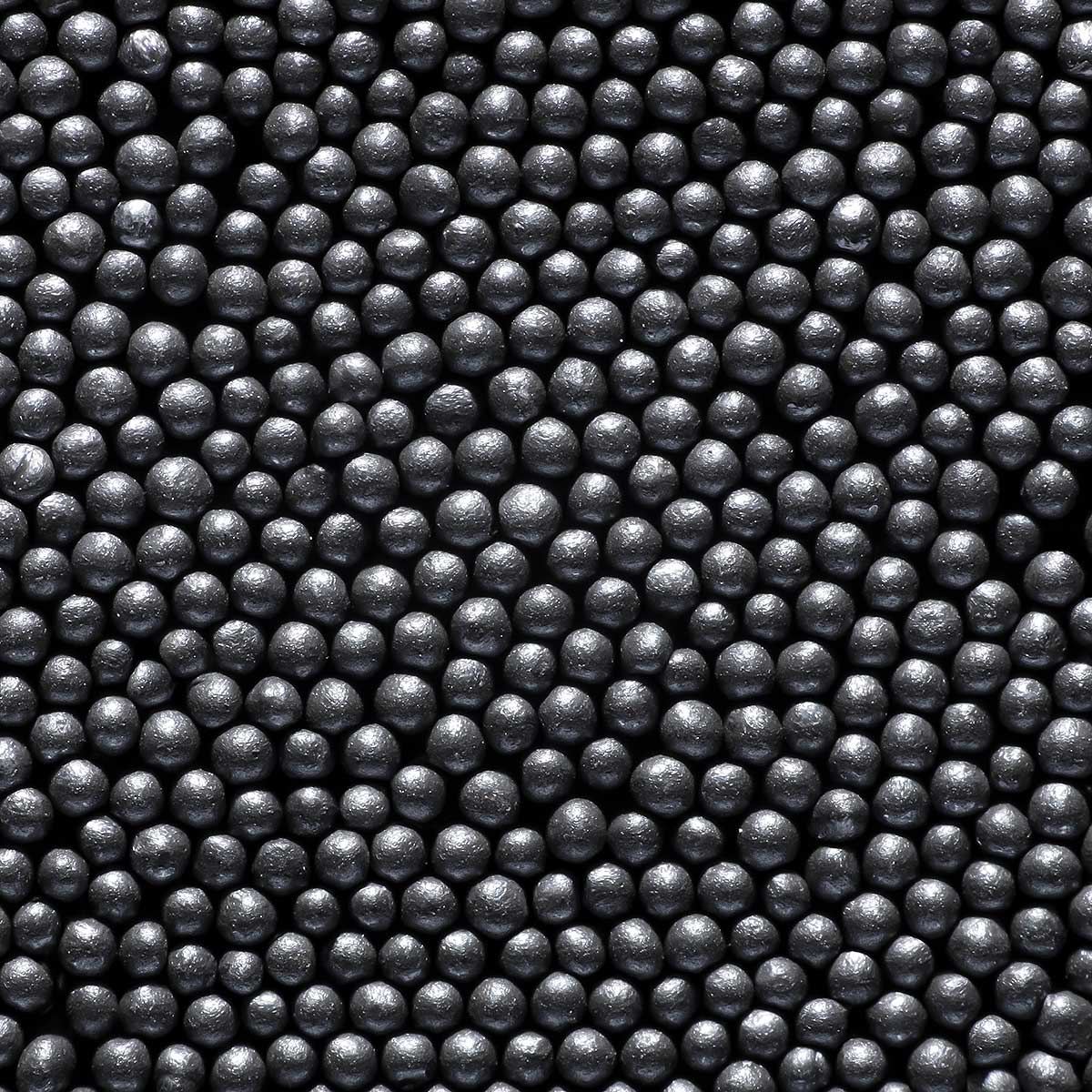

Shot blasting involves firing small particles against the surface of the metal or material in use – most commonly through compressed air or deploying a centrifuge. Choosing the right abrasive blasting products can give your material an even finish, the ability to clean products without damaging them, a direct reduction in overall cost fo the blasting process and much more.

What services do Ervin Provide?

In addition to our process optimisation and technical support for customers shot blasting operations services, we provide a range of abrasive products that can help process or prepare your metal as needed. These include-

Amasteel: Manufactured to the highest international specifications, Amasteel can be deployed for cleaning, surface preparation, shot peening, or cutting. This makes it effective when dealing with foundry and forge work, and in the construction, fabrication, and energy sectors. The material is low cost and produces reduced dust, providing maximum returns and minimum waste without compromising health.

Amacast stainless steel shot: Perfect for surface preparation or cleaning, this is an ideal surface finishing product for a number of sectors where rust free and clean surfaces are vital. These shot blasting particles were originally developed for deployment in the aerospace sector and brings a high-grade level of care to any engineering, die casting, or forging tasks it is deployed in.

Amachrome: A high grade stainless steel shot abrasive, this product is most often deployed with an automatic wheel blast system to ensure the highest levels of quality and control. Most commonly used in aluminium die-casting, Amachrome is also perfect for deployment with granite and other natural stones to provide the finish that any project requires, especially non-ferrous applications.

Amagrit: A popular choice when surface preparation is a priority, the deployment of Amagrit ensures that your material is properly prepared and fit for use. This is popular as a replacement for aluminium oxide and for treating welded steel structures, stainless steel forgings, and preparing aluminium profiles for coating. Amagrit is made from stainless steel and is rust free.

Amapeen: Made up from high carbon steel shot, Amapeen is perfect for improving the material properties of a range of metals, ensuring that they are truly fit for purpose. Commonly used in the aerospace and automotive sectors, shot peening can be used with automatic wheel blast machines for high-intensity work or smaller air blast systems to help provide manual control over the application of the substrate.

Amacut: A multipurpose cutting solution, the robust power of Amacut can be deployed in a range of situations. This is particularly useful for handling natural materials and carrying out stonecutting – allowing you to minimise wastage, maximise control, and ensure that your materials are safely prepared.

Get in touch

At Ervin, we understand the importance of providing clients with the right tools and shot blasting media for the job. If you need further guidance about shot blasting, you can review our regularly updated blogs here. These cover a range of topics and help ensure you make the right choices with your work. If you need further help, please do not hesitate to get in touch directly and let our team know exactly what you need for your bespoke project.