Energy Consumption

A shot blasting machine is often one of the highest consumers of energy in the workplace. It uses a great deal of energy to perform several important functions. Not only does it power the wheels that fire abrasive at the work piece, but it also transports the blasting media, and drives the material handling and extraction systems which remove fine waste and dust from the blasting process.

A study of shot blasting processes in foundries in 1997 calculated that energy costs were around 8% of the total cost of blasting. Other key cost areas were labour, maintenance, abrasive consumption and machine depreciation. In the intervening 25 years, the cost of all these factors has risen of course, but the worldwide energy price rises in the second half of 2021, early 2022 and the projected further increases through the remainder of 2022 strongly suggest that energy costs are now a significantly higher proportion of the total cost of blasting.

As all businesses battle to keep costs under control, energy efficiency in the blasting process is probably more critical now than at any time. There are a number of ways that users can help keep the costs of energy in their shot blasting process to a minimum:

Wheel Efficiency

The electricity required to run the wheels of a shot blast machine is likely to be up to 50% of the total power drawn by the machine (incl. its extraction system). Ensuring that these run as efficiently as possible is key to the reduction in energy costs. This can be done in a number of different ways:

• Control cage settings – ensure that the maximum number of particles hit the work piece with regular blast pattern checks.

• Maintenance – worn or broken wheel assemblies can reduce the effectiveness of the blast pattern, and cause excessive friction and waste energy.

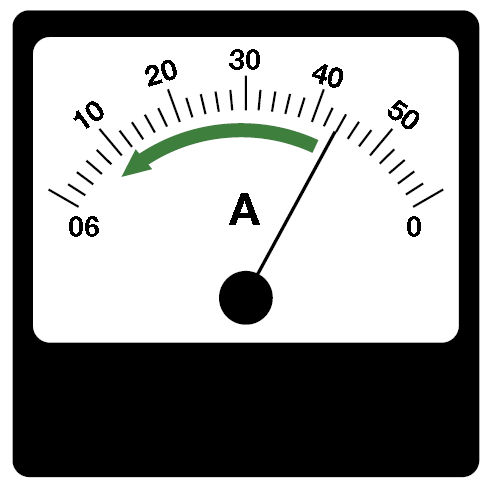

• Reduce amps – the main way to lower energy costs of the wheels is to reduce the amps and throw less abrasive. Care must be taken to maintain the required surface finish. In many cases, this will only be possible with careful abrasive selection.

Abrasive selection

If a reduction in amps, or a quicker blasting time, can help reduce rising energy costs, then one of the best ways to achieve this is through careful abrasive selection. Not only investigating the type of abrasive used, but also its size, shape and hardness. Ervin has local technical support to help assess your blasting process and develop an ideal product tailored to your blasting needs. Its dedicated Test Centre in Germany also undertakes detailed and customer-focused investigations. No two processes are identical, and finding an ideal steel or stainless steel abrasive solution can reduce your overall process costs.

Blasting times

Expert advice on abrasive selection can also create the opportunity for quicker blasting of work pieces, whilst ensuring the correct cleanliness and profile result is achieved.

When measured in terms of the quantity of product blasted (for example tonnes of work pieces or m2 blasted), faster blasting is demonstrably more efficient and means cycle times can be reduced or throughput speed increased, reducing energy consumption.

Operating Mix

It is important to maintain a balanced abrasive operating mix to ensure the best blasting result, in terms of both impact and coverage on the work piece. Using a tool such as the Ervin Spot Check Kit can help with regular monitoring of this crucial aspect. Without this control, blast times can increase significantly.

Maintenance

Keeping a machine well maintained, especially moving parts, can reduce wasted energy. In particular checking the condition of wheel assemblies (impeller, control cage, blades) can improve efficiency.

Ervin are ready to help you assess the energy consumption of your shot blasting process and provide you with the most cost-effective blasting solution.