- What is the difference between shot blasting, abrasive blasting and sandblasting?

- What materials can be used for shot blasting?

- Why is shot blasting used?

- How does shot blasting work?

- Who would use shot blasting?

- What are the benefits of shot blasting?

- When was shot blasting first created?

- Optimising the shot blasting process?

- What different types of shot blasting are there?

- What safety measures have to be considered when doing shot blasting?

- What equipment is used in the shot blasting process?

- How can Ervin help someone who needs shot blasting?

- What type of media can be used for shot blasting?

- Why is the quality of shot blasting media important?

What is Shot Blasting?

An essential part of preparing materials for use or further manufacturing processes – shot blasting involves the application of metal shot to the material of choice – most commonly metals. Used in almost every industry that involves the use of metals or hard substances, deploying shot blasting can help improve the aesthetics, qualities, and toughness of the material.

Deploying shot blasting strips any unrequired elements from the material of choice. Simple in process but complex in execution, carrying out the task requires a highly skilled team that understands the risks involved, how to minimise wastage, and secure the highest degree of effectiveness possible.

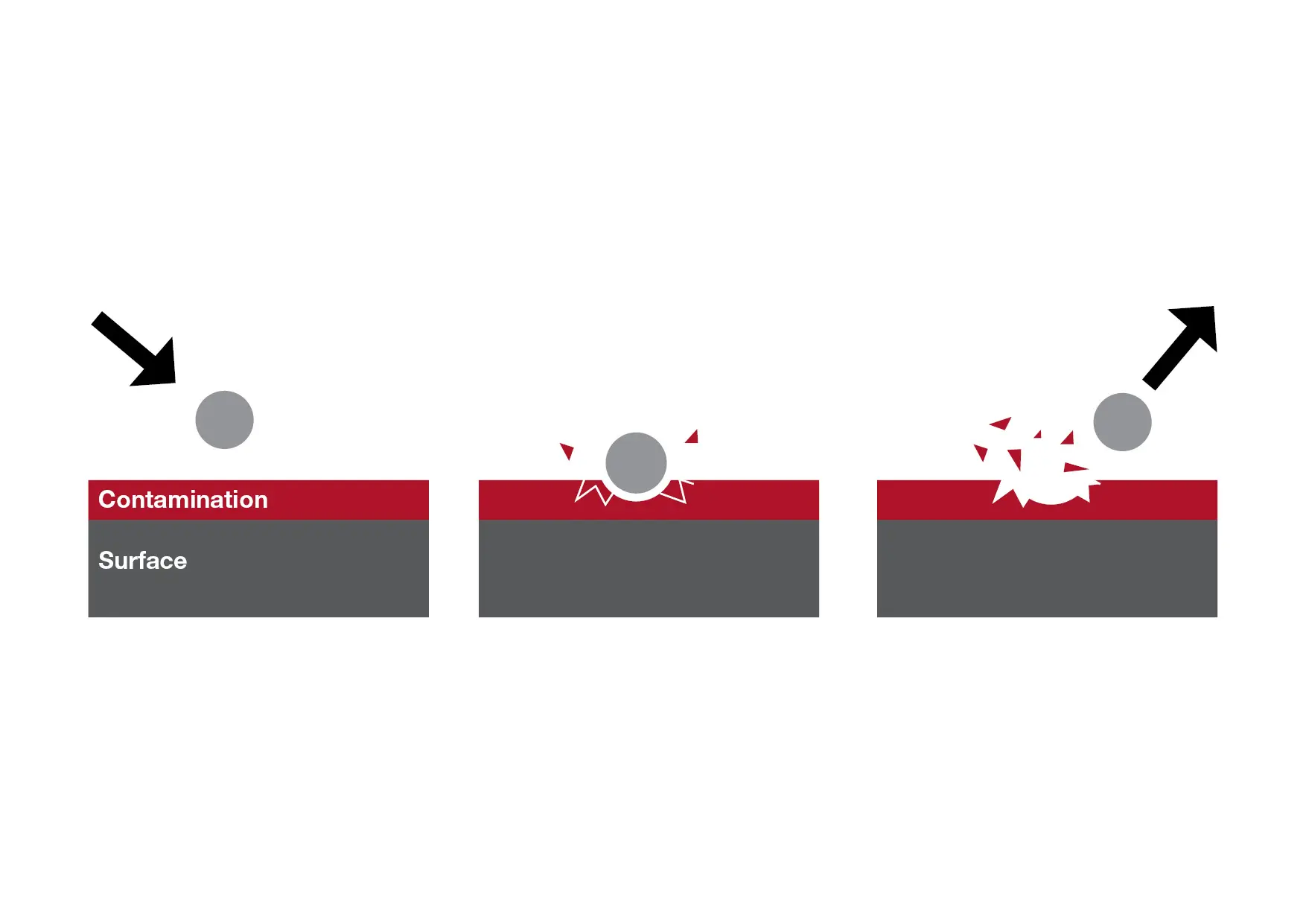

Shot blasting involves the deployment of a high-quality abrasive that is expelled against the material at force. These tiny elements strip or abrade the top layer of the material, removing imperfections, rust and cosmetic damage, or dirt – fully preparing it for use or follow-on treatments. For example: a common use for shot blasting is to strip the top layer of older or damaged materials for repainting. This removes any time related damage, caked on layers of paint, or rust. This can range from the treatment of a single pole or small, specific object, or range to entire vehicles or vast sheets of metal.

If the hardness of the abrasive is increased, this can help with increasing the efficiency and productivity of peening, cutting, surface preparation and more.

Given the nature of the process, this is commonly deployed by a range of machines from an industrial scale air blaster to handheld modes and wheel machines – allowing full control over how the shot blasting work takes place. This can be customised even further by choosing a type of shot that suits the end goal for the material in question. Given the diverse range of practical applications for shot blasting, there are a wide range of products and devices to help carry out blasting actions on a small or large scale.

Deploying shot allows the refinement and improvement of the material, either preparing it for further treatment, cleaning, peening, or providing a final polish. This provides a high degree of control over the technique , affording a degree of flexibility to ensure that the material is treated exactly as required.

This degree of choice and capacity for flexibility makes it perfect for large-scale or demanding projects. The robust nature of shot blasting means that it can quickly and efficiently prepare or pre-treat the hardest of surfaces. It is particularly suited to industrial large-scale batch and continuous processes. This is seen in its prevalence across a wide range of industries – from cleaning rust from welding jobs, as part of foundry work, or stripping the hull of tanks in the military industrial sector. It also has multiple uses in the automotive sector where the ability to peen metal makes it essential for engine repair, which requires intensive abrasive treatment to be fully malleable and treatable.

While the process is relatively straightforward, the utmost care must be taken in its application. Any abrasive shot used in the blasting process will be propelled at extreme velocity and can cause significant harm to workers if the correct precautions are not taken. This can cause lacerations, puncture wounds, and worse. A poorly prepared blasting space can also result in significant material and property damage, causing significant loss of time and resources while the issue is properly addressed and cleared.

A highly flexible process that can help contribute toward mission critical goals; shot blasting’s ability to rapidly treat and transform the materials in question is hard to overstate. If applied with care and diligence, shot blasting can help improve the look, integrity, and longevity of any materials that undergo treatment. Using modern machinery and training can allow teams or contractors to work to the highest standards without compromise, ensuring that client expectations are met time and time again.

What is the difference between shot blasting, abrasive blasting and sandblasting?

Commonly confused, the two types of treatment have similar delivery methods but different materials and end goals.

So, what is shot or abrasive blasting and why is it so effective?

Put simply, shot blasting generally involves the use of metallic abrasive in an enclosed automatic wheel machine system. Abrasive blasting, often referred to as sand blasting, involves the use of many different metallic and mineral abrasives, or other finer elements. Abrasive or sand blasting will normally use compressed air and be manually operated. The toughness of the abrasive material also dictates how the two disciplines are used, with abrasive blasting often utilised to refine and smooth over imperfections in materials. This is often carried out through hand-held compressed air devices, giving the user a high degree of control over how the abrasive blasting takes place.

In shot blasting, a device known as a throwing wheel is commonly used. This is a specialised piece of machinery that allows the chosen shot to be safely and evenly applied to the metal in question. While there are many variables involved at every stage of the shot blasting process, this allows a high degree of control over the end product – letting the operator peen and clean as needed.

In some cases, this can involve a device known as a blast cabinet. This acts a little like a fume cabinet in the pharmaceutical industry and allows the safe application of the blasting material without fear of inhalation or membrane damage from debris.

When it comes to deploying abrasive blasting, the finer the material the more care needs to be taken. Sand is now rarely used in abrasive work, as the fine particles can easily cause lung damage – causing serious, debilitating conditions that can be aggravated within weeks or lie dormant for months. However, many still use the term sandblasting when referring to both shot and, especially, abrasive blasting.

Ultimately, the type of abrasive material selected depends upon the object requiring treatment. Using a finer grain of abrasive material through a sandblasting process produces a smoother final look to the surface. This is perfect for use in more gentle or organic material, giving a great deal of control over the look and feel of the final product. This is also essential for elements that have delicate or complex parts, such as electronic devices that need to be corrosion proof. Taking a little extra care and diligence can easily ensure that more delicate materials remain in one piece and do not experience any deformity or warping as part of the process.

Shot blasting is always best deployed when intensive abrasion is required during both batch and continuous processes, most commonly with harder metals that may be resistant to gentler forms of treatment. Choosing shot blasting is a fast working, intensive process that can quickly strip or prepare a material surface – making it helpful for a range of industrial applications.

While shot blasting is applied to metals, it is always important to remember that certain types are much more vulnerable to abrasion than others. Metals such as aluminium, beryllium, copper, magnesium, and zinc are extremely soft and can easily be subject to significant damage if subject to intensive abrasive shot blasting. This makes it essential to choose the right approach and metal abrasive materials.

What materials can be used for shot blasting?

Shot blasting is a heavy-duty form of abrasive blasting and, as a result, is commonly applied to durable materials. These will commonly be metals such as aluminium, stainless steel, iron, steel titanium, and more. Once chosen, the type of shot will allow the operator to control the effect on the chosen material.

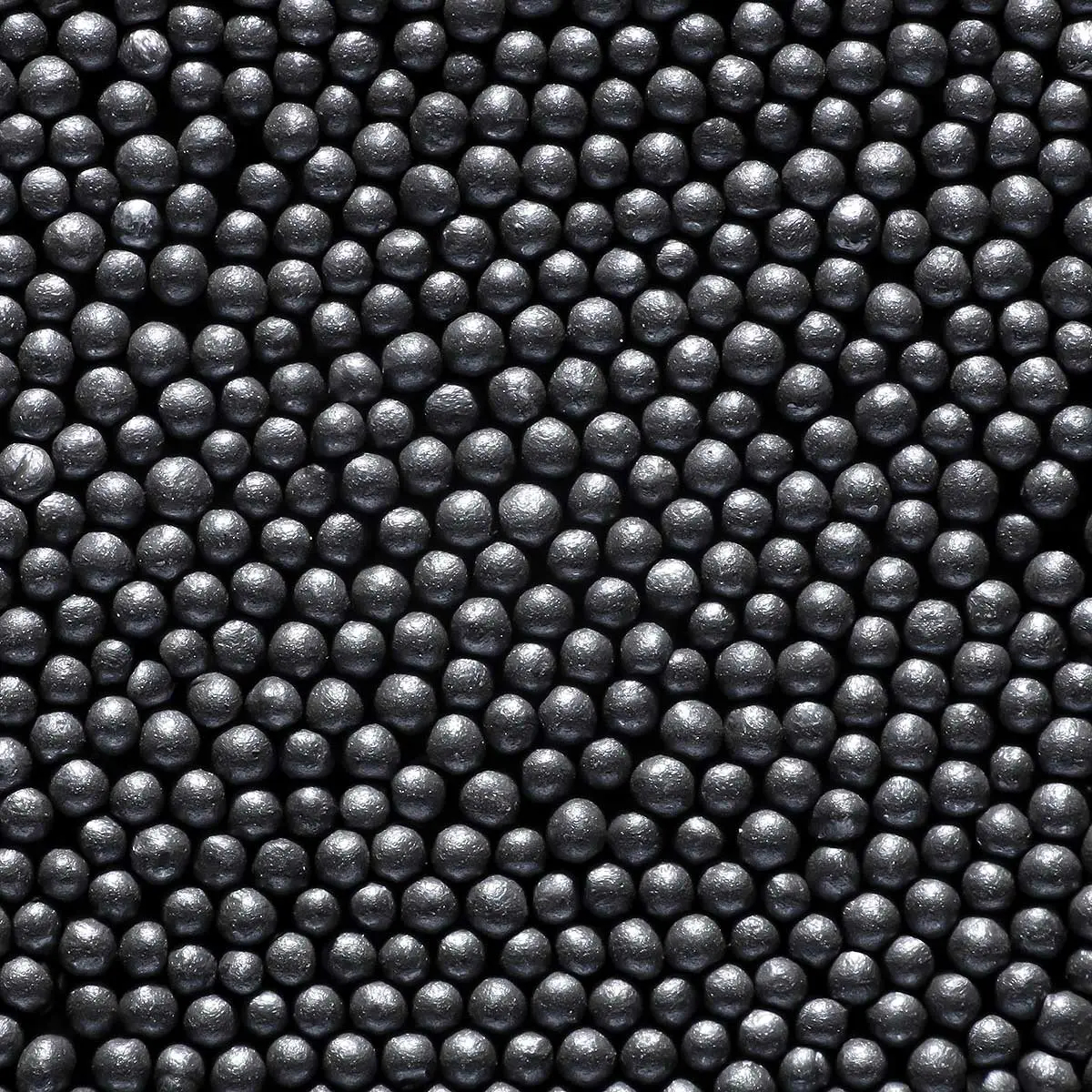

There is a wide range of shot available and choosing the right one can help ensure that the material is properly adjusted and fully fit for purpose. These are predominantly made from steel, ensuring a high degree of conformity and hard-wearing quality. While it is important to validate each object before putting it through the shot blasting process for the first time, there are broad categories of material that shot blasting can be used for.

These include-

Metals: Durable and hard wearing, metals can be extremely difficult or time consuming to treat by other abrasive means. Delicate sandblasting will often not have the power required to properly strip, peen, or pre-treat the surface and other options involving chemical treatment and bespoke methods are too resource intensive, time-consuming and can pose too many additional health, safety and environmental concerns to regularly use. Given the fact that there are a wide range of materials in an equally broad range of sectors, it is important to validate that the chosen shot blasting method is strong enough to fulfil the goal – such as stripping a top layer of material from the object – without causing too much damage or resulting in excessive waste.

Building Materials: Another commonly shot blasted material, concrete is incredibly hard wearing but can be regularly subject to staining and cosmetic damage. Given the popularity of concrete floors in modern architectural design and their necessity in warehousing and other fields, there are a range of specialist devices available to help treat significant amounts of concrete in small spans of time. Given the nature of the material, carefully applied shot blasting can skim the top layer and produce a characteristic smooth, clean effect. However, this has to be carefully monitored as deploying the wrong type of shot can cause chipping or cracking, resulting in a need for what can easily become significant repair work.

While it is important to fully vet the approach when shot blasting a new material, there are some elements that should never be shot blasted. These include-

Organic Materials: No matter how hard the material is believed to be, there is a very good chance that high velocity metal shot will cause significant damage. The most commonly affected material in these situations is wood, which can result in splintering, integral damage, and embedding shot deep in the material which can be dangerous if it is intended to cut or re-shape it. If it is important to resurface the material, other less intensive approaches such as sand blasting can produce a similar effect without resulting in damage or warping.

Plastics: Brittle as a rule, even the hardest plastics will not stand up to even the finest grade of abrasive shot. This will commonly cause splintering or punch holes clean through the material, ruining its usability or causing irreparable damage to its overall integrity. If it is intended to strip a layer from a plastic object, this will only cause significant scratching that will ruin the look of the object. This often causes more problems than were present initially, with deep grooves and cuts causing issues for any follow-on treatment processes. In many cases, using a lighter, non-metallic abrasive delivered through a water medium can help produce the desired results. Alternatively, using water alone through a high-pressure hose system can also be extremely effective.

Aesthetic Materials: Maintaining the look and feel of a structure can be a driver for regular cleaning. Unfortunately, with rare exception, a heavy-duty abrasive process should never be applied to sensitive or pliant building materials. Bricks will quickly fragment, plaster will crack, and slates will shatter and chip. In a situation where an abrasive approach is necessary, it can be helpful to consider less damaging options such as soda blasting.

The nature of shot blasting means that the metal shot can cause potential risk for members of the public and team members alike. Pellets can easily deflect and cause damage to windows, property, or other more delicate surfaces. Taking the proper time and care to protect users, team members, and visitors is absolutely essential.

However, if undertaken with care and diligence, shot blasting can be a useful addition to the toolkit that allows maximum choice and flexibility in its application with minimal risk. And with a wealth of options available to individuals from the public and private sector, it’s an easy addition.

Why is shot blasting used?

An essential part of a number of treatment processes, shot blasting has a number of unique uses. Some of these include-

Dealing with tough metals: The more resilient or denser a material is, the more difficult it is to shape or remove impurities. If this is the case, shot blasting can help quickly and effectively remove lumps and bumps, smoothing over any problems that less intensive methods would be unable to handle. This opens up additional options for treatment and ensures that, no matter the metal or material that is being handled, its strength and durability will not be an issue when it comes to blasting needs.

Any shot blasting provider will also be able to provide a range of shot for various materials and goals. This can be used to quickly thin out imperfections without causing further damage. Or for more sensitive materials, finer grains of shot and differing tools can be used to provide complete control over the process.

Peening: A mission-critical task for many sectors, peening uses force to strengthen a metal and make it more fit for purpose. Peening is a type of cold working process that involves the use of metal shot to create plastic deformation – causing what is known as ‘strain hardening’. This allows the material to become atomically stronger and withstand greater stresses without buckling.

This is deployed in sectors where material strength is a must such as aeronautical, military, automotive and emergency services. Conventionally applied by hammering or manually working a metal, shot blasting allows the operator to reliably achieve the same results in a fraction of the time with a high degree of consistency.

Cleaning: Shot blasting is often used to remove unwanted contaminants from the surface of the work piece. These contaminants will vary depending on the type of work involved. Typical uses of cleaning with shot blasting are; sand from castings, scale and mill scale from forgings and other metallic components, corrosion and previous layers of paint or other coatings

Pre-Treatment: Perhaps the best-known use of shot blasting, pre-treatment involves preparing the surface of a metal for certain procedures such as wet paint, powder coating, nickel coating, and more. This removes any impurities from the material and ensures a desirable surface roughness profile to provide the best possible base layer for any future coats. The ideal profile provides a “key” which aids coating adhesion and performance over its lifetime

While it is possible to skip this step entirely, it is rarely advisable when it comes to correctly covering the chosen material. Failing to properly blast a surface can result in an uneven and aesthetically unpleasing finish at best and providing a product that is unfit for purpose and potentially dangerous at worst. Poor surface preparation can lead to reduced coating life, increased corrosion, and part failure

Rust Removal: A close cousin to cleaning, removing rust from metals and materials is an exceptionally important task for a number of industries. Where this may be costly and time consuming through conventional means, using shot blasting allows for the quick removal of rust. This can be applied regularly or – if rust keeps returning to the material – shot blasting can be applied to fully strip and even out the material. Once complete, the materials can then have a protective coating applied to it to prevent further rust and keep it in active service for longer.

How does shot blasting work?

While there is a great deal of specificity involved, shot blasting involves the application of ‘shot’ or metal particles and fragments at high velocity toward the material to be treated. When struck, this provides an abrasive effect on the material, stripping away any unwanted impurities and helping to strengthen and properly prepare the metal for future use. Or, if used in gang saws, hard grit can help with the cutting of stone and other softer metals.

While shot blasting is a highly effective process in the right hands, it is vitally important to understand how the process works and the elements at play when applying the solution to materials. Failing to think through the shot blasting processes can result in damage to the material in question, considerable material wastage, inefficiency, and even harm to the teams undertaking the work.

While there are a range of different shot blasting tools, any modern system is made up of six key components. These include-

- a) Shot Delivery System: This controls how the chosen shot is physically applied to the metal in question. This comes in two forms, either through compressed air or through an enclosed centrifuge. If the shot is applied through a compressed air unit, this can be mounted on a mechanical arm or applied manually. This helps with delicate work on smaller or unusually shaped objects. If a centrifuge is deployed, this involves the use of as many individual turbines as required to properly cover the object in question. This is commonly utilised in an enclosed system, providing maximum safety but potentially causing issues with full coverage if the object is irregularly sized or positioned incorrectly.

- b) Material Recovery System: If shot is not continuously recycled, the process becomes highly inefficient and uneconomical. As a result, any shot blasting system should deploy a material recovery element that allows for ‘constant cleaning’. This is normally enabled through a collection mechanism that captures fallen shot, feeding it back into the blasting equipment. This is then filtered internally in the machine to remove contaminants from the metal shot before adding it back into the machine for repeated use.

- c) Air Filtration System: One of the major risks of conducting shot blasting comes from the tiny particles that can fragment and enter the air. This can create a poor working environment and should be controlled to mitigate risk. . This may involve the deployment of baffles, replaceable cartridges, or both. It is essential that the dust collector is checked to ensure it is fit for purpose as the production of high-volume contaminants can result in a drop-off in efficiency and the introduction of risk to the work.

- d) Blasting Area: This is normally handled by having shot blasting take place in a blast cabinet, preventing any risks of contamination or spillage from the work. These are also made from hardened materials to prevent high velocity shot from penetrating the cabinet or ricocheting around inside the space and causing damage to equipment or operators. These can also be sealed, reducing air pressure, and preventing contaminants from entering the air of the workspace.

- e) Transport: When shot blasting is undertaken, it is critically important that the material being blasted is safely and correctly secured via the workpiece transport system. This normally involves turn blast machines for bulk work or spinner hanger machines for larger, denser pieces. If the work involves high-velocity peening, it is important to seek out specialised equipment to ensure that it will not be damaged by the peening shot and that there is a way to safely ensure even coverage without placing the operator at risk.

- f) Control Unit: This allows the operator to start, stop, and manage the shot blasting process. If automation is possible, it is still important for the operator to understand the process involved with manually starting the machinery and its safe operation for the task at hand. As with all industrial equipment, every operator should be fully familiar with the emergency stop functionality on the system and the location of the emergency stop button on the shop floor.

Bearing this in mind, there are three key elements to check in order to undertake the shot blasting work successfully. These include-

Size: Choosing the right size of shot helps ensure that the desired results are achieved. These come in a range of styles and are offered by providers for specific purposes. For example, larger particles are required for heavily contaminated parts, or for surfaces requiring a high degree of roughness prior to coating.

Ask: What task am I undertaking and what type of shot is best to complete it efficiently?

Speed: Depending on what kind of surface texture is required from the metal or other material, it’s important to monitor the speed that the shot will be applied to the surface. Simply put, the faster the shot is travelling at the surface, the harder the impact and rougher the surface and vice versa. This should also be combined with coverage, which ensures all the work pieces are evenly blasted. In a wheel machine this depends on the number, position and direction of the blast wheels. In an air blasting system, a slow, steady sweeping application provides a more even coat. On the other hand, remaining in the one spot will result in a highly textured, irregular coverage – which may be essential for site-specific abrasion.

Ask: What speed will the shot be applied at and does that accomplish my objective?

Volume: The amount of shot administered to the materials controls how effective the blasting approach will be. Finding a balance between the three key variables (size, speed, and volume) will ensure even, successful treatment. However, this also raises a real-world business issue with economy. It is important to check and double check that the right amount of shot is being applied to complete the project successfully and remain within budget. The more shot directly applied to the material, the more dramatic and effective the change will be.

Ask: How much shot needs to be applied to the material and how much needs to be purchased for the work to be complete?

If all three are balanced and accounted for correctly, the shot blasting work will be conducted successfully.

Please note: While many tools exist that make the process easier, shot blasting is a delicate and potentially dangerous process. If undertaking the work, always ensure that physical safety is given a high degree of prominence as individual pieces of shot can be highly dangerous.

Who would use shot blasting?

With an ability to strengthen, strip, and pre-prepare metals for treatment – shot blasting is present across a range of industries.

Some leading examples include-

Shipbuilding: Being able to clean and prepare large volumes of metal makes shot blasting a tremendous asset for a range of maritime industries – from commercial shipping to luxury sailing. Shot blasting can be used to quickly strip the paint from hulls and other materials or to prepare surfaces for new paint jobs. This can massively cut down on the time and subsequent cost of maintenance, with smaller portable units able to carry out spot-work as needed, reducing resource expenditure when it matters most.

Industrial Applications: A range of sectors can make use of shot blasting work, particularly those that rely on machinery with high upkeep needs or working on silos, plants, and refineries. This can be applied to large sheet metals such as steel, letting them be fully prepared with relative ease. In many cases, shot blasting is not limited to metalwork, with shot often used to carry out aesthetic blasting on concrete, brickwork, and other materials.

Automotive Industry: Shot blasting supports the automotive industry at component level, by providing the means to clean work pieces in both foundries and forges. Many parts of both commercial and private vehicles are shot blasted prior to manufacturing. As well as removing sand or scale from components, shot blasting allows for the treatment of larger units such as coaches, buses, and trucks before painting, and the removal of rust or detritus from older models. Due to its flexibility, effectiveness, and cost-efficiency, shot blasting is used in the cleaning and preparation of many parts and pieces. This can be as simple as cleaning transmissions, to the peening of materials to increase their resistance properties. Or it can help with ongoing maintenance, allowing entire engine blocks to be cleaned and stripped with ease. This can also be applied to the creation of bicycles and motorbikes, who can have their frames quickly stripped and prepared for powder coatings and more. This also allows for mission critical build tasks such as properly peening a chassis or working to harden key engine parts before adding them to a build.

Masonry: Using heavy grades of shot can make it easy for professionals to help cleanly cut, abrade, or process stonework. This can help with the care and treatment of natural stone which requires significant attention to properly prepare, shape, and refine. Choosing the right grade of shot or grit can massively cut down on the time spent on cutting work with granite, marble, and more. This can help save in consumption costs for cutting work, help drive efficiency throughout the production pipeline, allowing team members to work safely, efficiently, and without any compromise on quality. This empowers businesses to develop and sustain a professional advantage in what is often a competitive marketplace, helping them deliver an exact and durable product.

Military: One of the most common uses for shot blasting techniques is to help with the cleaning of key equipment. This can range from individual car parts to intensive blasting for armour plated vehicles, letting them toughen and temper metals while ensuring that they are free of dirt and detritus. Peening can play a critical role in ensuring that aircraft are fully fit for purpose and able to handle the exacting pressures of flight. This also quickly allows for the addition of rubberised elements to metal fixtures, with shot blasting quickly stripping and preparing the surface for further treatment.

Construction: Shot blasting is a major part of the construction industry. It is used to clean and prepare structural steel prior to receiving a protective coating, as well as in the production of rebar. The quality of shot blasting is key to the performance and lifetime of many metallic components; it can also be used to help clean concrete floors for clients or ensure that any warehouse flooring is regularly treated and remains fit for purpose. This can be applied in a range of designs to introduce unique weathering to hardened objects or apply it with care to ceramics and marbles in a build to produce unique patterning with ease. Shot blasting can help with the cutting and reshaping of materials at the pre-deployment stage or allow the deployment of portable equipment to make any necessary changes or refinements on-site. Smaller portable units can also be transported from site to site, allowing shot blasting to become a bespoke task or in the use of a blasting room to help with the treatment of larger metal pieces.

Metal working: The iron and steel working industries apply shot blasting on an almost daily basis. This can be used for descaling items, stripping the paint from older equipment, and removing rust and detritus. This also extends to foundry work, where blasting can be used to clean impurities from freshly cast parts and help with homogenising a range of material surfaces. Add in a capacity to maintain heavy machinery, pre-treat metals, or carry out peening work and it’s no surprise that the sector utilises shot blasting to such a high degree.

Aviation: Shot peening is a mission critical step in airplane design – with high grade shot often used to toughen key components to make them more resistant to damage or fatigue. Recent innovations have made handheld and portable shot blasting devices a regular fixture on runways throughout the world. Smaller machines are used to renew the toughness and grip on airport travel tracks or work away any irregularities or damage without causing significant downtime. This can also be applied to changes to paintwork, ensuring that any broken engines are cleaned and repaired successfully.

Rail Maintenance: An essential part of maintenance for fleets of vehicles, shot blasting is regularly used in the preparation of rails and to help prepare and strip trains for painting or regular mechanical treatment. This allows for the cleaning of heavy-use engine parts and helping to properly prepare metal surfaces before applying a protective coating. This enables teams to easily carry out preventive maintenance and remove any rust or debris, allowing businesses to minimise disruption and deploy a cost-effective ‘stitch in time’ to help drive down operational costs.

Ervin case study peening page

Ervin case study peening page

Energy Industries: As with industrial work, this sector places a heavy degree of emphasis on preparing surfaces before painting, applying powder coatings, or other treatments. This also helps with the peening and pre-treatment of pump rods, pipe coating, wind towers and other on-site machinery that supports key working goals.

What are the benefits of shot blasting?

Choosing shot blasting can bring a number of benefits. Some of the key advantages include-

Increased Speed: If undertaken by a trained professional, shot blasting can massively cut down on time spent manually stripping or manipulating the metal in question. Depending on the type of delivery system, this can involve a high degree of process automation. This ensures consistency when it matters most and allows the provision of a fit-for-purpose end product for clients or internal teams. This allows even the largest or most unwieldy items to be quickly dealt with and the removal of many manual obstacles that can massively slow down the shot blasting process.

Preventative Maintenance: Along with the ability to refine and shape metals, shot blasting can play an important role in the maintenance of mission critical gear and equipment. Carefully applied shot blasting can be used to clear rust from equipment, remove impurities from metals, and help strip the paint from a range of objects. This can help prepare items for a fresh protective coating or prevent the build-up of ferrous materials that can erode the structural integrity of an object.

High Efficiency: Along with speed, modern shot blasting equipment allows for increased efficiency and consistency when it comes to completing any work or projects. This allows for a uniform finish on the final product and lets employees work with ease. Finding a balance between the type, volume, and speed of shot also allows the operator to work at an increased rate without compromising on the quality of the end product. In addition, the ability to strip, prep, and change metals through one piece of kit often proves extremely useful and using shot blasting equipment allows all three key process steps to be undertaken with ease.

Choice in Metal Treatment: Being able to treat metals can increase the longevity and strength of key materials. This allows for the peening of plating and smaller materials to ensure that they are fit for purpose. In addition to preparing items for powder coating and other treatments, it adds an ability to adjust the look and feel of metals with ease – allowing builds or products and parts to look amazing as well as perform their job flawlessly.

Very Cost Effective: While shot blasting is a highly technical process, the raw elements are simple and relatively inexpensive. Depending on the type of shot required, it can often be sourced by a professional provider at an affordable rate; all while still adhering to international quality standards. Many machines also allow for the recycling of shot, making the most out of any chosen particles.

Fully Customisable: Shot blasting has a number of key uses that can be highly customised, allowing a flexible approach to projects and handling issues of all shapes and sizes. This allows a dynamic approach to the work, with many shot blasting devices allowing engagement with smaller metallic items, larger builds, or taking a client-specific approach to the work. This can be as simple as changing the type of shot, varying the practical approach, or changing the kit that has been chosen. This enables all requests to be safely met – ensuring the highest standards of quality for the tightest of turnarounds.

Long Established Technique: Having existed for decades, modern approaches to shot blasting enjoy tried-and-tested experience coupled with a modern approach. This helps users remain reassured about the quality of their work and ensure the highest standards of professional excellence, by being able to fall back on industry experience. . This gives a massive range of choices when it comes to selecting the right approach and helps account for potential issues that are found well in advance.

Environmentally friendly: Shot blasting is one of the most environmentally friendly methods of metal treatment, allowing a massive reduction in the wastage that is involved through recycling the shot and taking an eco-conscious approach to daily use. Deploying shot blasting does not involve any harmful chemical elements in the work and massively cuts down on the harmful dust that is created through conventional sandblasting – with any hazardous materials easily captured and recycled as needed. Conventionally, high quality shot and grit can be recycled for up to 600-1000 unique “cycles” or applications, helping to minimise waste and the creation of detritus.

Safe and Sound: Despite the degree of force applied by shot blasting equipment, deploying it correctly and responsibly can eliminate a massive amount of risk for users. This can take the form of eliminating excessive physical work, ensuring that harmful fumes are contained, and preventing any pellets from escaping beyond the demarcated workspace. This allows demanding metalworking tasks to be carried out in security and safety with the absolute minimum of risk to team members.

When was shot blasting first created?

Abrasive blasting is a long-standing finishing process that has a long and colourful history. However, like many tools that we currently enjoy, the origins of abrasive blasting can be found in nature.

Many historians believe that the inspiration for abrasive blasting came from the oceans. Our shoreline dwelling ancestors saw the raw power of the waves and how the combination of water and sand particles helped erode stone, cut furrows into solid rock, and remove imperfections over time. However, while the idea existed for generations, it was one creative individual who took the steps to bring it into the real world.

One of the first instruments to provide abrasive blasting came from the hands of an American soldier called Benjamin Chew Tilghman. Born in 1821, Tilghman came from a military family that placed emphasis on education and self-improvement, with the inventor graduating with a degree in Law in 1839. However, Tilghman never chose to practice and instead decided to pursue his lifelong passion for inventing. This saw him travel throughout Europe for most of his young adulthood with his brother – visiting sites of industry such as mills, factories, and laboratories to learn more about the challenges they faced.

After the outbreak of the Civil War, Tilghman quickly rose through the ranks before earning the title of Colonel before being seriously injured in 1863 at the infamous Battle of Chancellorsville. Following the war, he was promoted to the rank of Brigadier General for valorous conduct and spent the time following his recuperation tinkering with his inventions.

Inspired by the effect sand had on the windows of his barracks while still a soldier, Tilghman thought up the process of sandblasting – using water and sand for a range of purposes from sharpening knives and utensils, carrying out etching, weathering wood and much more. The inventor lodged his first patent in 1870 and produced a second refined patent in 1877 – calling it the liquid grindstone.

In a perfect example of serendipity, the liquid grindstone caught on in a flash – with many businesses deploying it in the UK to keep their tools and utensils in top working order. Tilghman then decided to take a closer look at the possibilities abrasive blasting presented and began to experiment with different materials.

Research led him to create a process for producing abrasive level iron shot – not unlike the highly effective materials still used today. This involved the pouring of molten metal into cold water and collecting the small shot that was produced. This was then used for the cutting of stone, producing the first dedicated shot blasting process in 1872 – using it for masonry work and for a wide range of other applications.

The inventor continued to work on new ideas until the time of his death. Some of Tilghman’s abrasive patents included-

US No. 104408:

Creation of Sandblasting – Awarded 1870

US No. 133501:

“Improvement in cutting stone and other hard substances” – Awarded 1872

US No. 187239:

“Production of Iron Shot” – Awarded 1872

UK No. 13510:

“Roughening Iron and Steel Rolls” – Awarded 1885

Of course, this idea did not take place in isolation. Shortly after Tilghman’s death another inventor called Louis D. Peik continued to build on Tilghman’s research by developing a process known as wheel blasting. This allowed for improved abrasion through the application of a wheel-like device known then as a “Wheelabrator”. This was explicitly designed to help with the cleaning of metal castings and used a wheel to ‘propel’ sand, stone, iron shot, and other required elements to scour clean the surface of castings.

Finally, Peik decided to explicitly combine the two and in 1934, achieved the formal patent for “Treating Metal Surfaces” or as the inventor put it in his patent submission “Our invention relates to the removal of the outer layer of scale or oxide from metal articles such as plates and billets, by means of a stream of abrasive particles…in a very effective manner, with great rapidity, and at very low cost”. Building on Tilghman’s work, Peik and his collaborators finally cemented a practical, reliable process for shot blasting – starting a wheel turning on an industry that has never slowed down.

First launched in 1933, Peik’s Wheelabrators were quickly licensed for use throughout the United Kingdom. And after acquiring 40% of the Tilghman company, the business was renamed to Tilghman Wheelabrator before changing to American Wheelabrator in 1973, paving the way for the continuous improvement we see throughout the sector to this very day.

Optimising the shot blasting process?

A highly skilled and complex process, shot blasting should only ever be undertaken by trained individuals in a professional setting. While technology such as ridable or hand-held shot blasting machines are increasingly popular, the process for shot blasting metals and materials remains broadly the same.

The standard shot blasting process is split into two key approaches, mechanical shot blasting and air blasting. No matter what process is selected, shot blasting involves the following steps-

Examining the materials: Before beginning the shot blasting process, it is important to a) look at the materials to be treated, b) decide what the end goal is, and c) determine the best path of execution. If dealing with non-metal elements and materials, choosing a less intensive method of abrasive blasting such as sand blasting may be appropriate. If working with metals, shot blasting will commonly be the best option available.

Once the best approach is selected, it is important to validate the end goal. For example: does the material need to be peened, stripped of rust, or prepared for a protective coating? After this is confirmed, it is important to settle on how to accomplish the goal. This involves looking at the grade of shot to be applied and how the abrasive process is completed. If it is intended to carry out relatively fine work such as cleaning smaller metal objects such as forgings, screws, and parts, a smaller hand-held device may be of use. If larger items such as chassis and lengths of pipe or building materials are to be blasted, choosing a larger enclosed option may be worthwhile.

Along with the approach, it is critical to decide on the gauge of shot that to be used. Depending on the provider, a range of different grades or types of shot will be available. These will be for different purposes but come in two key types-

Steel Shot: These are uniformly round metal balls, commonly produced through the cooling of molten metal. These are commonly used to change the roughness of a surface, an object or provide uniform peening.

Steel Grit: These are sharply angled, irregularly shaped steel objects. This is created by taking steel shot and crushing it, producing a more abrasive substance that can be found in a wide range of hardness and sizes.

If required, ‘sand’ can also be deployed for finer work. This is commonly made from non-metallic material with abrasive qualities such as silicon carbides or aluminium oxides. However, these are generally not suitable for hard metals and introduce a risk of silicosis from inhalation due to the size of the particle matter.

Once the approach has been confirmed and validated, the shot blasting process can be undertaken. While there are many different options available when it comes to applying shot to the chosen material, they will fall into two key categories-

Air Blasting Work: This involves the use of compressed air to drive the chosen type of steel shot toward its target. This can be accompanied by a range of automated options to help ensure the highest standards of safety, coverage, and quality.

NB: This is most often used on specialist or smaller items, with larger elements taking more time and care to safely cover.

Mechanical Blasting Work: This involves the shot being driven toward a target through the use of powered turbines. This helps speed the process and provide quick coverage without compromising on quality.

NB: This is most often used in industrial settings or for larger items that may take too much time to cover through air blasting.

Assessment/Follow Up: When the cycle of work is complete, the equipment is safely shut down and material assessed. The number of cycles should always be agreed in advance to save on time and effort but can potentially be ‘eyeballed’ on unique or sensitive pieces. If more work is required, the process repeats. If the correct amount of abrasion has been applied, the process stops, and the shot and detritus is safely cleared away.

Like any process, there are also a number of common pitfalls that can be easy to stumble into. If undertaking any shot blasting work, it is vitally important to consider these pitfalls. Some easy mistakes include-

Over Peening/Over Blasting: This is particularly important for physically demanding work. While peening can increase the fatigue strength of the chosen material, it is important to fully understand and validate how vulnerable the material is to compressive stress. This can quickly lead to breakages, resource expenditure and significant loss of time. Care should also be taken at areas where the material is not uniformly thick or thin, with undue pressure often causing breakages or excessive warping.

Being Unfit for Purpose: when undertaking shot blasting, it is best to ensure that the shot is right for the job. If the process is dealing with plastics, rubbers, wiring, or softer metals, time should be taken to ensure that the chosen shot will not damage the material. If this is the case, abrasive blasting with finer material can often prove to be a better choice.

Process Control: Failing to properly control the shot blasting process can not only lead to poor final results, but in a loss of efficiency to the overall production process. If the chosen shot blasting machine is not correctly set up, this could lead to problems such as loss of useful abrasive or excessive wear to the system.

Final Result: If blasting is being undertaken to prepare a material for a powder or paint coating, it is important to check that the material is uniformly cleaned before passing to the next step. Any contamination or particles can reduce the effectiveness of a follow-on coating, resulting in a poor-quality covering that can be susceptible to rust and damage. Care should be taken that the necessary standards and specifications for both cleanliness and surface roughness profile are followed.

What different types of shot blasting are there?

When it comes to contemporary shot blasting, there are three key approaches-

1.Air Blasting: This involves a manual operator applying shot directly to the material. This incorporates the chosen type of shot being pushed by compressed air towards the material to be abraded. This allows the operator to control the type, volume, and speed of the shot. As a rule, air blasting is carried out in a dedicated cabinet or room and often involves a high degree of automation.

This enables the process to be almost completely interaction free or require intervention from the professional conducting the blasting. When all the safety checks are done and the process begins, the chosen shot will be propelled from a hardened nozzle to the object in question. This can be manually manipulated and may involve the use of hand-held shot blasting equipment to ensure full coverage.

2.Mechanical or ‘Wheel’ Blasting: This involves the shot being driven by a rotating wheel to help circulate it over the metal or material of choice. Once the material has been selected, this is affixed to the cabinet, allowing for the object to be moved during the blasting process. This is also commonly called ‘airless’ blasting due to the use of turbines to provide coverage. The enclosed nature of the unit means that any shot material can be applied with minimal effort on the part of an operator.

Given the modular nature of modern mechanical design, these units are often highly customisable. This can be as simple as adding a conveyor belt system to cut processing time or add elements that can help with peening, deflashing, and more.

3.Floor Blasting: Increasingly commonplace due to the prevalence of high-quality concrete flooring and roads, floor blasting involves the direct application of steel shot to the chosen surface. These can be ride-along models or dedicated hand-held kits to ensure correct coverage when it matters most.

While this process is generally straightforward, it does highlight potential issues with air quality and safety with other staff members. When carried out, air quality and personal safety should be of the highest importance, letting the work be completed on time and without incident.

However, when it comes to daily and industrial use – wheel blasting is often the most commonly used approach.

What safety measures have to be considered when doing shot blasting?

When it comes to conducting shot blasting, there are two key issues that all operators need to be aware of – the risk from debris, and the risk of inhalation.

Lung damage is a constant concern when undertaking any abrasive blasting process. The nature of any abrasive work means that small particles of material are projected at force toward the desired target. This sends matter into the air, which can often take a long period of time to dissipate. While any trained professional will be OSHA compliant and operate their device in a secure, well maintained area, fine particles can be a major cause of environmental and health concern.

Any abrasive blasting action is also extremely loud. Due care and attention should be applied to wearing hearing protection at all times when shot blasting processes are taking place.

While metal shot may be made of larger materials, this introduces additional risk due to the velocity that they are applied. Always ensure that any machine equipment being used has a completely up to date maintenance record and that OSHA compliant eye and face protection is worn, along with safety shoes and gloves.

If these elements are a concern, it is worth remembering these five key actions to maximise worker safety:

- a) Consider Material Alternatives: If the project involves the use of fine or potentially toxic shot blasting material, consult the provider or on-site manager to source a less harmful alternative. Remember that in many situations, a selection of abrasives can be deployed with a water carrier to minimise the risk of dust. However, no process is entirely fool proof and it’s always worth properly reviewing the chosen material before deploying it on site.

- b) Consider Physical Safety: As shot blasting involves metal fragments travelling at high velocity in an enclosed space, it is essential that the utmost care is taken to provide correct protection for workers or contractors operating the machinery and that it is carried out in an appropriate, secure location. At a minimum, this should involve erecting appropriate barriers between the blasting room or the area where shot blasting is taking place and restricting access for individuals or visitors who may come into contact with the work by accident. Even if the project being undertaken is small in scale, ensure that it is conducted in an appropriate blasting room or through a blast cabinet. Where the size of the project does not allow this, ensure that restrictions are in place for the work as infractions can result in serious injury.

- c) Consider Airflow: Any abrasive work involves the creation of particulate matter that can be significantly dangerous when it comes to inhalation. While steel, grit, or other shot materials are less likely to cause lung damage, the risk is still high. Many other materials can be dangerous and even toxic if inhaled or if they get under the skin through injury. This makes it essential to deploy a full exhaust and safety system for workers that will help safely capture dust and ensure the long-term safety of staff and operators.

- d) Think about Training: When it comes to deploying shot blasting in the workspace, it is vitally important to ensure that all individuals are fully trained in the use of the equipment. This will allow the maintenance of uniform quality and enable the team to operate safely, minimising physical risk to themselves and ensuring that any visitors and colleagues are protected from harm.

- e) Remember maintenance: If conducted by a trained and professional team, shot blasting is a safe and effective process. However, given the nature of the materials that are being worked with and the velocity at which they are applied, it is important to ensure that any of the shot blasting equipment has a fully up to date service history and all elements are operating correctly.

What equipment is used in the shot blasting process?

There are two types of equipment involved when undertaking shot blasting work – free hand equipment and enclosed equipment. These include:

Wheel Blasting Equipment: Wheel blasting units are designed to evenly treat materials by rotating a turbine wheel through electrical power. Designed to be sustainable and efficient, these come in a range of capacities and designs – allowing them to accommodate large objects at significant rates of rotation. These are specifically applied for larger items where the surface of the item has to be aggressively cleaned – making them perfect for rust removal, peening, sanding and cleaning.

Wheel blasting equipment can come in the form of table machines which are specifically designed to help with the treatment of broadly asymmetrical items. This allows the user to position and manipulate the item as required, letting parts be loaded and processed as needed.

If additional manual control is needed, a dedicated gripper tool can be chosen. This allows for robot assisted handing. These tools are highly programmable and can be set up as needed to manipulate materials mid-cycle, helping save time and ensuring maximum coverage on the material being blasted. These can be combined with roller conveyor system to save even more time and make the materials and product handling even more straightforward.

Air Blasting Equipment: Commonly deployed in conjunction with a dedicated blast cabinet, this method involves the use of compressed air to propel the chosen abrasive material at the object in question. The degree of impact helps strip unwanted elements from the metal, peen the surface of the item, or carry out whatever other task is desired.

If the abrasive power of shot blasting is too much or there are worries about material residue, wet blasting could be considered – applying the shot through water. This can be assisted by any number of free hand tools or through the use of automation – allowing the perfect balance between performance, safety, and effectiveness to be found. These nozzles can be suction, or pressure fed, making them perfect for operating at high volume or minimising resource expenditure at key points in the workflow.

While the overall approach is important for shot blasting correctly and safely, there are three key criteria of equipment that see regular use. Modern shot blasting work will include the deployment of at least one of following-

Portable Blasting Gear

As the name suggests, these units are designed to be taken on site, rented, or deployed on an ad hoc basis for certain builds and projects. They involve the use of a compressor unit that utilises air to drive the chosen grade of shot toward its target. Once the abrasive material is chosen, it is loaded into distinct tanks on the kit that can then be transported directly to the site or project, providing a high degree of flexibility in how the work is tackled. These can be mounted on trailers or can be small enough to be transported in the back of a van – maximising portability and increasing the range of options available when tackling a problem on-site.

Blasting Cabinets

These are used for more hazardous or demanding blasting work. A cabinet is designed to provide the maximum benefit by containing the abrasive work within an enclosed space. This allows for the recycling of shot and eliminates any inhalation risks for the individual overseeing the process. Any waste material produced by the system is collected by the filtration unit and shot is safely cleaned and recycled to avoid machine fouling which can often lead to breakdowns or excessive wear and tear.

Cabinets are often manually operated by team members who manually control the blasting equipment – using a dedicated pedal to control the rate of spray and protective sealed gloves to safely manipulate the abraded object. This process can also involve automation throughout the process, from allowing for a simple start up to adding armatures, belts, or specialised equipment to help speed up the processing of work.

These most often deploy a hardened nozzle and the use of a suction blast or pressure blast system. Also known as ‘siphon’ blasting, suction blasting uses a compressed air source to create negative pressure in the chamber of the blast gun. This draws the chosen shot into the reservoir and allows the user to direct it as required toward the material. The alternative option is to use a pressure blast system that uses a sealed, pressurised canister to store the abrasive material. When it needs to be deployed, the blast hose is activated, and the pressure forces the material out at a controlled rate towards the chosen target.

Blasting Rooms

Commonly deployed in industrial scale abrasive activity, a shot blasting room is a large-scale version of a blast cabinet. Designed to accommodate larger or single-piece items, this sealed environment provides the space necessary to carry out the work. This can involve the stripping of sheet metal from ships hulls, to large scale items such as rail cars, planes, or other vehicles.

Hermetically secured, these items use an air filtration system to help draw away dust and reduce the risk of fouling. They are also highly modular and able to be adjusted to accommodate a range of equipment, items, and tools.

While each blast room serves a different purpose from the next, they are made up from a range of shared, core components. These commonly include but are not limited to-

– Air Filtration System: Designed to work in tandem with the seal on the space, these collect debris particles and reduce the risk of silicosis for those operating in the space. This eliminates the risk of internal and external contamination to team members and the item being abraded.

– Blasting Apparatus: This includes the bespoke blasting system necessary to carry out the work. This can involve a turbine system, several air blasting units, or a combination of both to fulfil the blasting objectives.

– Material Recycling System: This system is designed to collect, clean, and repurpose shot that has already been used in the blasting process. This can involve the use of a pneumatic collection system or manual sweeping and reclamation for the teams operating in the space.

– Sealed Enclosure: These are secure to prevent contamination for individuals outside the room and potentially allow for the recycling of shot where required.

– Shot Container: These sealed containers store the grade of shot required to complete the work.

The space can be further customised by adding additional devices and automation elements. This can be as simple as dedicated cranes and apparatus to move the item being shot blasted or involve the use of robot armatures to help safely manipulate heavy or odd-shaped items. This can also include emergency safety shut off switches or baffles to help eliminate the risk of sound bleed – allowing the process to be safely carried out without causing hearing damage to others operating on site.

How can Ervin help someone who needs shot blasting?

Shot blasting can be extremely difficult to master and our team is on hand to provide the professional guidance and world class quality of service needed. Most users will agree that the key to successful shot blasting is not only selecting the right type of media to use (metallic/expendable etc), but which size, shape and hardness will give the highest productivity and the lowest cost.

Some advantages of working with us include-

Comprehensive Experience: With 100 years’ professional experience, we understand the importance of ensuring our teams are trained and ready to help with all shot blasting needs. This means helping customers find the right product for their unique business requirements and supplying guidance about how best to get the results they are looking for. Once we have helped our customer to select the best abrasive, we have local technical expertise to support optimisation and continuous improvement to their process.

High Quality Products: At Ervin, we pride ourselves on providing best in class care and product quality. This means working to provide a product that supplies a range of benefits. These include-

Reduced Consumption: Our shot blasting materials are designed to provide maximum benefit and minimal cost. This brings down the amount of steel shot required to get the desired result, driving efficiency and lowering costs.

Highest Productivity, Lowest Cost; Choosing the right shot and grit means Ervin customers can work smarter and faster, thus reducing the overall cost of their blasting process. The cost of the shot blasting process is rarely dependant on the purchase price of the abrasive

Quality Performance: Each of our shot blasting products are developed to the highest of international standards and made with world-class craftsmanship throughout the EU and USA. This can guarantee consistent abrasive performance.

Range: Our range of products provides a solution for all shot blasting related business requirements. Whether customers are keen to clean, prepare the surface of their product, conduct exacting peening, or cut material – we have a type of shot to suit every need.

Solutions Finder: For customers who don’t know where to begin with their shot blasting needs or want to validate their decision we offer our Solutions Finder. This lets them quickly choose one of the core purposes of shot blasting and quickly land on a material solution that works for them – saving time and effort and allowing our team to provide the guidance that they need.

For those who want to learn more about our current range of products and services our product range can be reviewed fully from here. Any specific questions or queries around our current product range or unique business issues faced by our customers can be dealt with by a direct enquiry, letting our team know exactly what material is to be blasted efficiently, effectively, and with the highest standards of quality.

What type of media can be used for shot blasting?

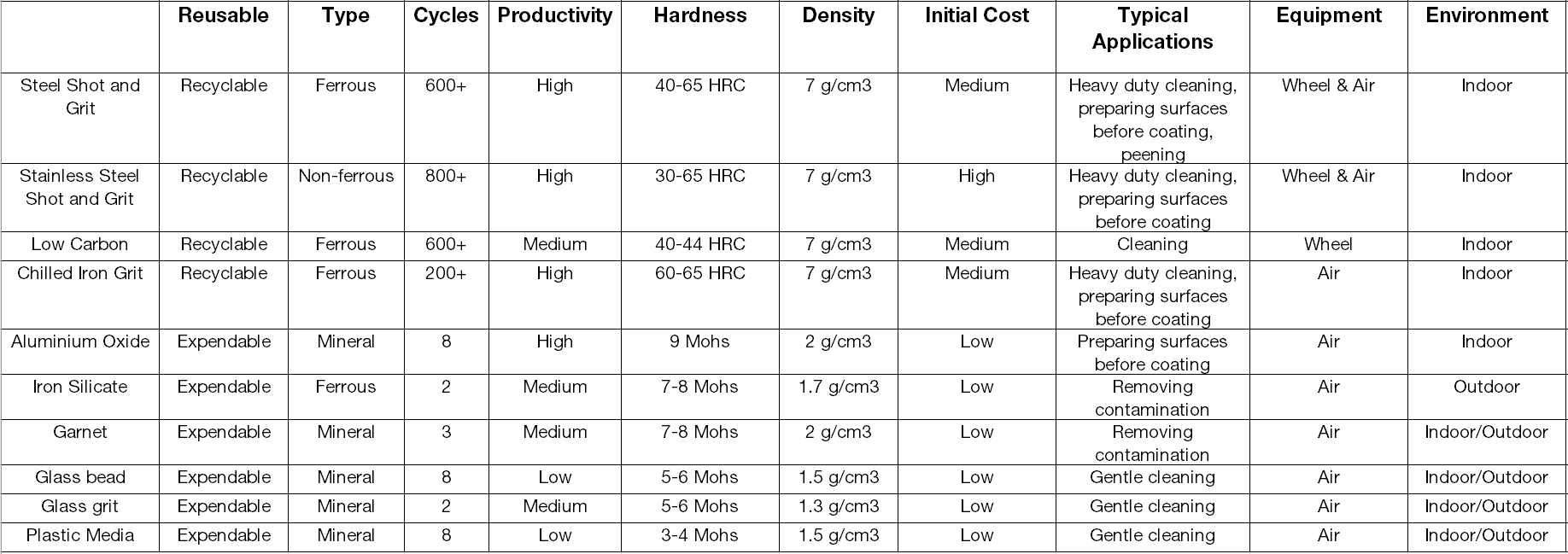

The various different types of media to be used for shot blasting can be separated into two main groups – recyclable (generally metallic) and expendable (usually mineral) abrasive. Recyclable metallic abrasives, such as steel and stainless steel shot and grit, can be used hundreds of times, but require an encapsulating recovery system. If this equipment is available, they offer the best value choice in terms of productivity, cleaning ability and cost. Mineral abrasives only last a handful of uses, and often have an inert chemical composition which gives them the benefit of outdoor use on site. An abrasive comparison table can be seen below.

Why is the quality of shot blasting media important?

The quality of shot blasting media will have a big impact on a number of factors; cleaning speed, surface roughness or texture after blasting, the amount of abrasive consumed. All this ultimately affects the productivity and total cost of the blasting process. For example, higher quality steel shot and grit has the right balance of chemistry and uniform martensitic microstructure, to make it both durable and able to transmit more energy. The best shot and grits last longer, reducing consumption, and are also able to transmit more energy to the work piece on each impact. Therefore, high quality abrasive cleans or peens faster with lower process energy costs. Having a well-controlled size grading and hardness range means the exactly the right abrasive can be found for every job.