What is Amacast?

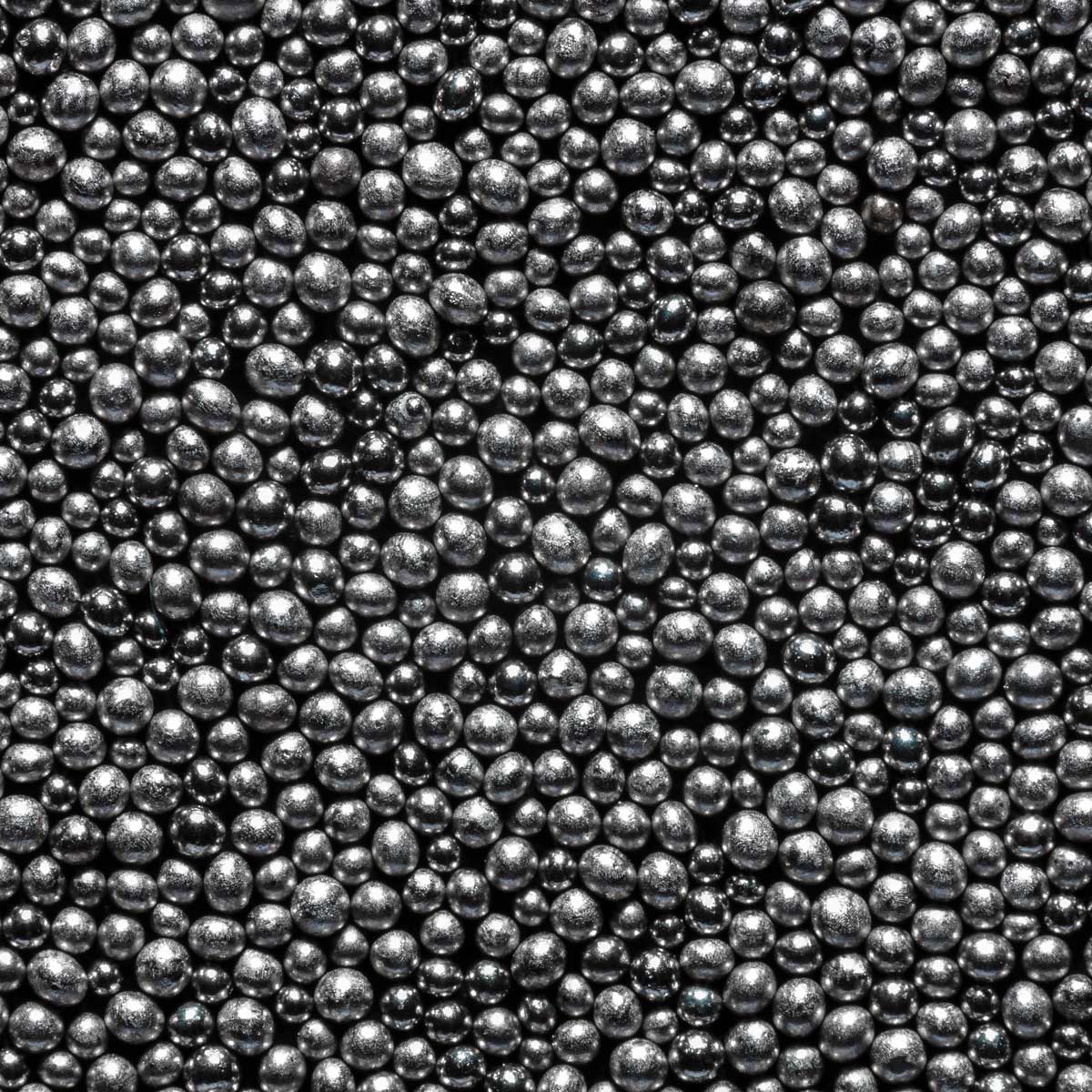

One of our core Ervin abrasives, Amacast, is stainless steel shot designed to help with a wide range of abrasive blasting projects. Designed to be effective across a wide range of applications, Amacast can be deployed with automatic wheel blast machines and air blast machines with equal confidence.

Produced in Tecumseh, USA – Amacast is fully compliant with the most demanding of industry standards, with each particle developed using a process created to cater effectively for the aerospace and defence sectors. This ensures the highest possible standards in quality control and allows for dependable consistency from one project to the next.

What are the benefits?

All of Ervin’s stainless steel abrasives are developed with consistency, performance, and efficiency in mind. This significantly reduces the rate of material consumption, reducing wear on your delivery equipment and allowing you to enjoy a high degree of productivity at significantly reduced cost.

The range of Amacast stainless shot also allows you to get the most out of whatever purpose the abrasive is turned to – letting you enjoy an even surface, polished and finished metal, and more.

What processes can Amacast be used in?

Amacast is designed to be a multi-purpose shot blasting solution. This allows you to deploy it in projects that require surface preparation for additional work, surface cleaning for rust and preventative care, and finishing work to help ensure an immaculate final appearance. In particular, Amacast can be used in the processes where rust free surfaces are necessary.

This makes it helpful in a range of applications, especially when dealing with high-quality or potentially sensitive parts or materials. Many clients choose to deploy Amacast with die casting work, in particular with the use of expensive, delicate or non-ferrous materials such as aluminium, zinc, brass, or stainless steel. The exacting manufacturing process allows you complete control over how Amacast is applied – ensuring a reliable end product without ever having to compromise on quality.

Being able to control how it is deployed makes Amacast perfect for engineering projects, especially those that deal with welded stainless-steel structures or reworking metal elements before coating work. With each batch created to the highest standards, this allows you to forge ahead with your mission critical tasks while ensuring your employees, contractors, and materials remain safe and sound.

What next?

If you want to add value to your blasting work, Ervin is the right partner. With many years’ professional experience, our team will work with you from the first point of contact to understand and validate your project needs. This allows us to provide an abrasive blasting solution that is truly fit for purpose, empowering you to enjoy exceptional control over your work and a high quality end product.

If you want to learn more about Amacast or the rest of our line, you can view our complete abrasive blasting catalogue in full from here. Or if you have any additional questions, queries, or project needs – please do not hesitate to contact us directly and let us know how we can help support your ongoing work.